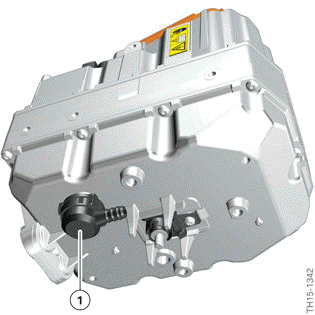

BMW 3: Connection for potential compensation lines

The isolation monitoring determines whether the isolation resistance between active high-voltage components (e.g. high-voltage cables) and ground is above or below a required minimum value. If the isolation resistance falls below the minimum value, the danger exists that the vehicle parts will be energized with hazardous voltage. If a person were to touch a second active high-voltage component, he or she would be at risk of electric shock.

There is therefore fully automatic isolation monitoring for the high-voltage system of the G20 PHEV. It is performed by the battery management electronics at regular intervals while the high-voltage system is active. Ground serves as the reference potential. Without additional measures only local isolation faults in the high-voltage battery unit could be determined in this way. However, it is equally important to identify isolation faults from the high-voltage cables in the vehicle to ground. For this reason all the electrically conductive housings of high-voltage components are conductively connected to ground.

In this way isolation faults in the entire high-voltage electrical system can be identified from a central point by the isolation monitoring.

The high-voltage system must not be operated if the potential compensation cables are not properly connected to the high-voltage components.

If in the event of a repair the high-voltage components or the body components are replaced, the following must be observed during assembly: The connection between the housing and the body must be properly re-established. The repair instructions must be strictly observed (clean/corrosion- free/unpainted contact surfaces, tightening torques, documentation).

Connections for coolant lines

The Electrical Machine Electronics is cooled by a separate coolant circuit. The coolant connections can be seen in the graphic at the beginning of this subchapter.

Ventilation holes

The bottom of the housing is provided with a ventilation feature to prevent water (resulting from temperature changes and thus possible condensation of air moisture) from collecting inside the Electrical Machine Electronics. This ventilation feature also enables pressure equalization between the inside of the housing and the surrounding area. To fulfil these two tasks, the ventilation feature has a diaphragm that is permeable for gases but impermeable for fluids.

Ventilation of the Electrical Machine Electronics

- Ventilation